If you’re looking for a way to improve your bakery business, then you should consider investing in customized industrial 4-strap bread baking pans. These bread tins are made to strap 4 loaves of bread at once, which makes the baking process much more efficient.

Not only will you be able to produce more bread loaf in less time, but your loaves will also come out looking and tasting great! In this article, we will discuss the benefits of using straped bread trays and how to order a custom-made tin.

We’ll also go over the dimensions and maintenance requirements of these baking trays so that you can make an informed decision before investing in a new set.

1. What Are Industrial 4-Stap Loaf Pans and What Are They Used for?

Industrial 4 strapped loaf pans are baking pans that have been designed to strap four loaves of bread at once. This is done in order to make the baking process more efficient, as it allows for more bread loaf to be produced in less time. Additionally, the use of these pans results in loaves that are evenly baked and have a consistent shape.

There are a few different things to consider when ordering a custom-made loaf pan, such as the dimensions and the type of bread loaf that will be baked in it. It is also important to keep in mind that these pans require some maintenance in order to keep them in good condition.

Industrial strapped pans with heavy gauge steel frame are baking tins with four compartments, each of the same size. They are used to bake bread loaf, which is then cut into slices of the same size. This ensures that each slice of bread loaf is the same thickness, making it easier to bake or serve with toppings.

The 4 strapped loaf pans are available with or without handles. Handled tins are easy to pick up from the oven or trolley rack, while handleless baking pans have the advantage of being placed closer together on the baking sheet, thus reducing wasted space.

2. Benefits of Using Custom 4-Strap Baking Bread Pan

The main benefit of using a custom Industry loaf pan is that it produces consistent results. By customizing the right toast box baking pan according to the specifications of the bread loaf product you are making for a better result.

Another benefit of using these baking trays is that they help to brown the bread loaf evenly. When bread is baked in a conventional oven, there is a chance that some parts may be overbaked while other parts may not get enough heat.

This results in an uneven browning of the bread loaf. However, when you use a custom baking box where all compartments are the same size, they receive equal heat, thus browning the bread evenly and achieving consistent bread quality results.

There are various other benefits to using these baking trays. They include.

-Ease of Use.

These baking trays come with a non-stick coating that makes them very easy to use. The bread slides out easily without sticking to the loaf pan. This makes cleanup very easy.

-Even Browning of the Bread.

As all compartments in these pans are the same size, they receive equal heat during baking. This results in an even browning of the bread loaf.

-Improved Production Capacity.

The use of these pans results in the bread being produced in less time. Additionally, The use of these pans results in loaves that are evenly baked and have a consistent shape. This helps to improve your production capacity.

– Reduced errors.

Baking bread loaf is a process that requires both time and temperature precision. The use of four loaf pans creates an environment where all 4 loaves are in the same conditions throughout the baking process. This reduces errors and makes it easier to produce consistent results.

Custom industrial 4- strap bread pan offer many benefits that make them a necessary tool for any baker looking to improve their production capacity, efficiency, and results.

-Durable and long lasting.

These baking pans are made from high-quality materials that make them superior durability and long lasting.

-Nonstick surface.

The non-stick coating on loaf pans makes it easy to remove the bread from the pan without damaging it. Additionally, the non-stick surface makes cleanup very easy.

-Even heat distribution.

The use of four loaf pans ensures that all loaves receive an equal amount of heat during baking. This results in an even browning of the bread.

-Easy to handle and store.

The four strap design makes it easy to handle and store the pans. The straps also make it easier to remove the bread from the pan.

3. What Are the Dimensions of A Custom-Made Commercial 4-Trap Loaf Pan?

Size is an important consideration when choosing a pan. The size of the pan will determine the size of the bread. It is important to choose a size that is appropriate for the amount of dough you will be using. If you are baking large loaves of bread, you will need a larger pan. Smaller pans are better suited for smaller.

-Loaf Pan’s Shape Sizes for 450g (1 lb) bread

Measurement tin size:

Top Inside (mm): 197 x 106

Bottom Outside (mm): 186 x 101

Vertical Depth (mm): 110

Material: 26 gauge aluminized steel / Aluminum

Coating: Teflon coating/ Silicone coating/ Silicone glaze

– Loaf Pan’s Shape Sizes for 600g (1.3 lb) bread

Measurement tin size:

Top Inside (mm): 309 x 91

Bottom Outside (mm): 300 x 84

Vertical Depth (mm): 107

Material: 26 gauge aluminized steel / Aluminum

Coating: Teflon coating/ Silicone coating/ Silicone glaze

– Loaf Pan’s Shape Sizes for 900g (2 lb) bread

Measurement tin size:

Top Inside (mm): 327 x 106

Bottom Outside (mm): 316 x 100

Vertical Depth (mm): 122

Material: 26 gauge aluminized steel / Aluminum

Coating: Teflon coating/ Silicone coating/ Silicone glaze

– Loaf Pan’s Shape Sizes for 1000g ( 2.2 lb ) bread

Measurement tin size:

Top Inside (mm): 327 x 121

Bottom Outside (mm): 312 x 119

Vertical Depth (mm): 120

Material: 26 gauge aluminized steel / Aluminum

Coating: Teflon coating/ Silicone coating/ Silicone glaze

– Loaf Pan’s Shape Sizes for 1200g ( 2.6 lb ) bread

Measurement tin size:

Top Inside (mm): 370 x 120

Bottom Outside (mm): 361 x 116

Vertical Depth (mm): 125

Material: 26 gauge aluminized steel / Aluminum

Coating: Teflon coating/ Silicone coating/ Silicone glaze

4. What to Consider When Making A Custom 4 Strap Loaf Pans?

There are a few things to consider when making custom four strap loaf pans.

-Materials

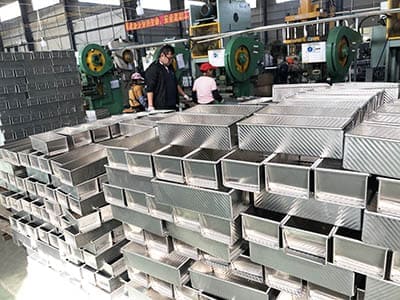

The materials used for industrial 4-strap baking pans are generally aluminum alloy and aluminized steel. The choice of material should be determined by the characteristics of the bread to be baked. Professional bakeries only use aluminum and aluminized steel baking pans because they are superior durability and last longer.

-Sizes

The size of the baking pan is also an important consideration. The size of the baking pan will determine how many loaves of bread can be produced at one time.

-Non stick finish

It is also important to consider the nonstick surface finish when choosing a baking pan. The nonstick surface finish makes it easier to remove the bread from the pan and makes cleanup very easy.

5.How to maintain your new custom Industrial 4-strap bread pan?

Once you have your new custom industrial four strap bread pan, it is important to take care of it so that it will last a long time.

-It is important to wash the loaf pan before using it for the first time. This will remove any residue that may be on the surface of the pan.

-After each use, it is important to wash the loaf pan in hot, soapy water.

-It is also important to avoid using metal utensils on the surface of the pan. This can scratch the surface of the pan and make it more difficult to clean.

-When storing the baking pan, it is important to make sure that it is stored in a cool, dry place. This will help to prevent the formation of rust on the surface of the pan.

By following these simple tips, you can ensure that your new custom industrial 4 strap bread pan will last for many years to come.

6. How Much Does A Custom Made 4-Strapped Bread Pan Cost?

The cost of a custom made 4 strap bread pan will vary depending on the size, material, and finish that you choose.

-4 Strap Pan loaf Pans Sizes

-The size of the pan will determine the price. The larger the pan, the more expensive it will be.

-Loaf Pans Materials

-The material that you choose will also affect the price. Aluminum is a cheaper option than aluminized steel.

-The finish that you choose will also play a role in the cost of the pan. Nonstick finishes are typically more expensive than anodized finishes.

-Non stick finish

The reference price for a 4-strap pans between $20.0 and $70.0. The price depends on the configuration of your pan, specifications, material, finish, etc. Please contact us to learn more about how to configure your baking pan and get an accurate quote.

7. Conclusion:

Custom made commercial 4 strap loaf pans are an important tool for any commercial bakery. They are available in a variety of sizes, materials, and finishes to suit the needs of any baker and bakeries.

When choosing a pan, it is important to consider the size, material, and finish that will best suit the bread you will be baking. By taking care of your new custom bread pan, you can ensure that it will last for many years to come.

8. Where to Choose The Right Commercial Loaf Pan Supplier?

When looking for a custom strap bread pan supplier, it is important to choose one that has experience in the industry. The supplier should be able to provide you with a variety of options to choose from and should be able to answer any questions that you may have.

In addition, the supplier should be able to provide you with a competitive great price for the custom pan that you choose.

TM baking company has been involved in the industrial bakery feild since 2007, designing and manufacturing bakeware. We are trusted baking pans supplier in China.

With a wide range of complementary products such as cooking sheet trays , muffin trays, baguettes trays, loaf pans, bun & roll pans, bakery trolleys, we manufacture high quality products at an a low prices and fast shipping for the international markets, restaurant equipment supplies, and we supply bakeware products to bakeries, commercial kitchens , restaurant supplies, and food manufacturing facilities.

-Read More Popular Articles:

https://tmbaking.com/what-is-the-great-baking-sheet-pan/

https://tmbaking.com/clean-the-grime-residue-on-baking-trays/

https://tmbaking.com/choosing-the-right-bread-pan/

https://tmbaking.com/strap-bread-pans/

https://tmbaking.com/buy-bread-pans/

https://tmbaking.com/clean-stainless-steel-bakery-trolleys/

https://tmbaking.com/choose-the-right-baguette-trays-supplier/

Need something different? Reach out us for more details! Our team are always happy to help. Thanks for reading! We hope this article was helpful.